LPL Checker – Fully Automated License Plate Lamp Testing System

Why Automate License Plate Lamp Measurements?

License plate illumination is regulated by varied standards worldwide (e.g. ECE, SAE, CCC).

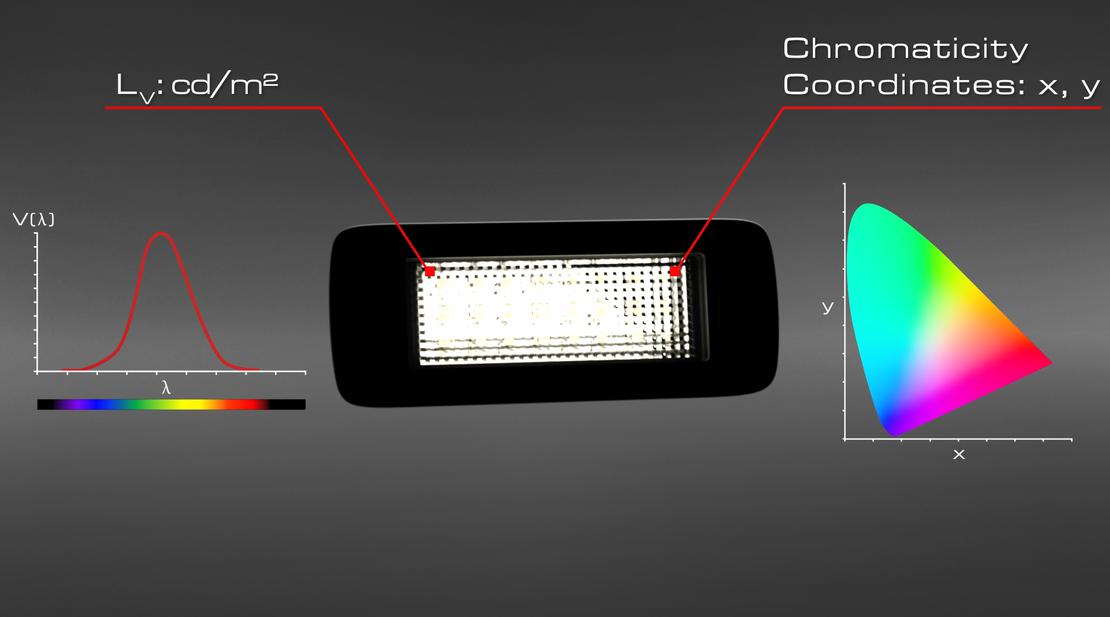

To certify compliance, the luminance and color coordinates of a license plate lamp must be measured. Manual positioning and alignment are error-prone and time-intensive.

The LPL Checker was developed to address these challenges with full automation, delivering consistent, repeatable, and standard-compliant results.

System Components – Robotics, Imaging & Software in Harmony

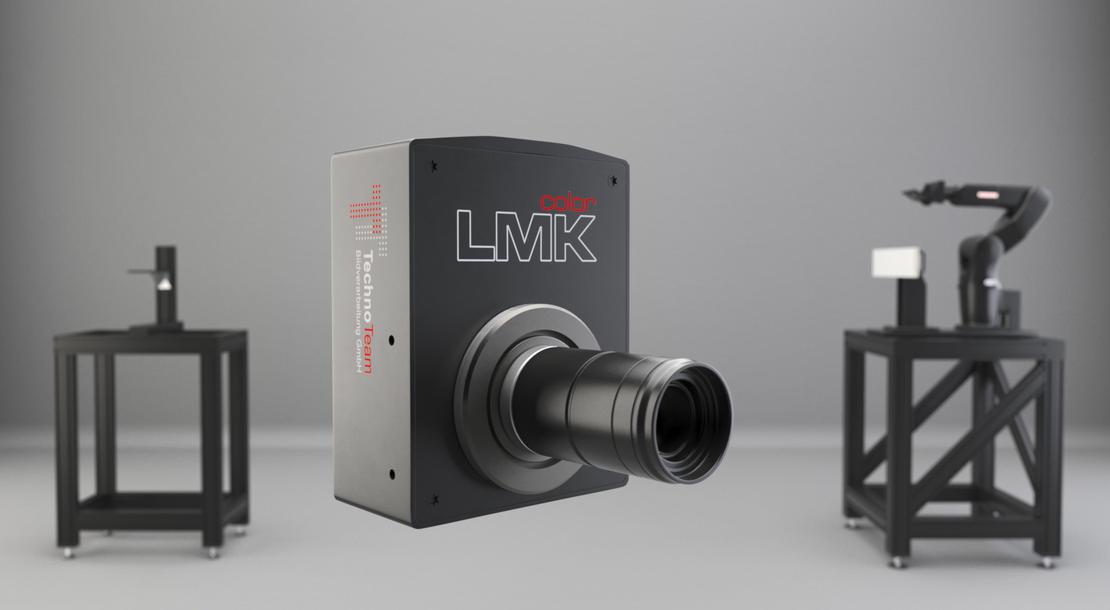

The LPL Checker system is built from three core, tightly integrated parts:

- LMK 6 or LMK 6 Color imaging photometer — captures luminance and color data across the reflective target in one frame

- DENSO Robot arm — positions the license plate lamp at all required angles with high repeatability

- LMK Light Checker LPL Software — controls robot motions, acquires images, performs in-depth analysis, and checks compliance with chosen standards

These components together form a seamless, automated platform that minimizes human error and maximizes throughput.

Key Advantages of the LPL Checker

- Fully automated operation – minimal manual intervention, consistent throughput

- Speed and efficiency – faster measurement cycles compared to manual approaches

- Precision and repeatability – robotic positioning and single-shot imaging minimize error

- Standards compliance – built-in checks against global licensing regulations

- Resource savings – less manpower, fewer retests, more reliable certification

Bring Compliance to Your Lab

Don’t leave license plate lamp compliance to chance. Contact TechnoTeam now to discuss a customized LPL Checker configuration — for turnkey installation, calibration, or integration with your test environment.

Downloads

Publications

- Type:

- Package

- Applications:

- Automotive

- Measurands:

- Light measurement

- Tasks:

- Automation & Industry