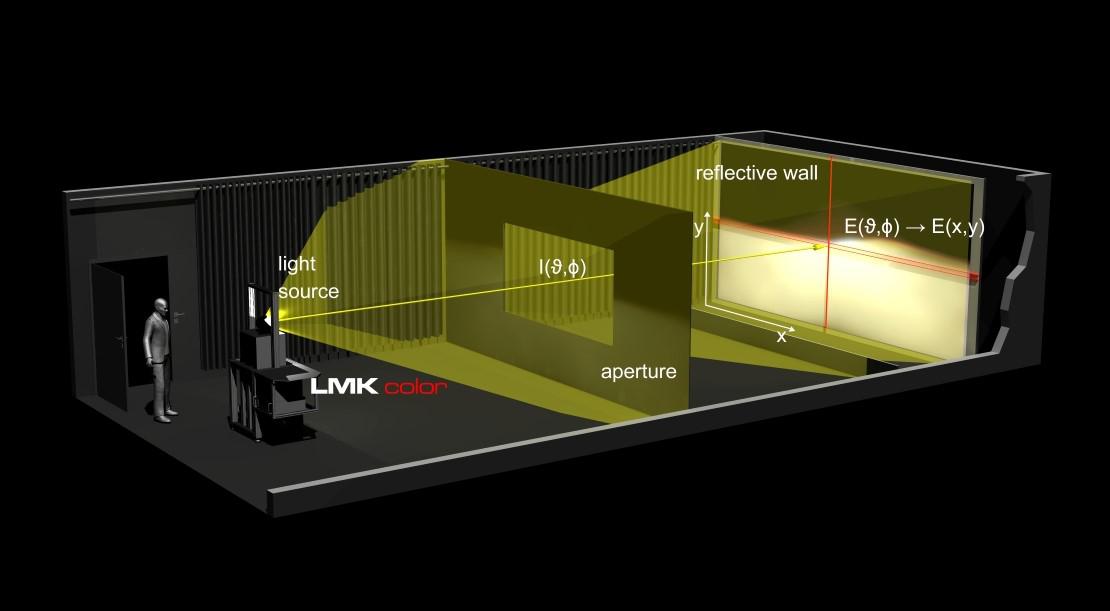

BV room - High-Precision Screen Photometry Lab System

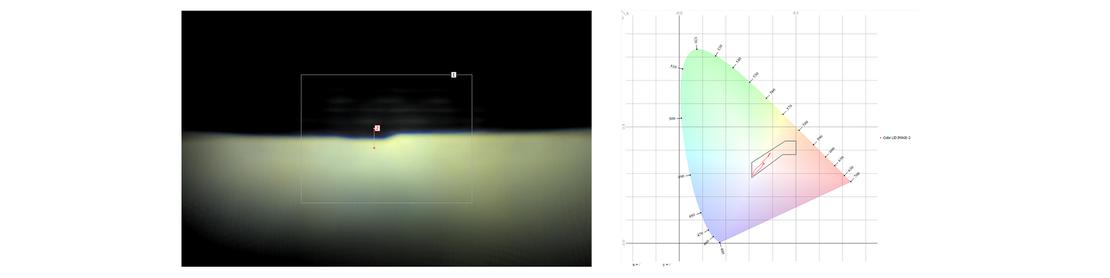

The BV Room is a specialized laboratory system designed for automotive lighting, and general lighting research. Built around our core product LMK, the BV Room combines optical precision and automated workflows for both R&D and quality assurance environments.

Engineered for Accuracy, Designed for Flexibility

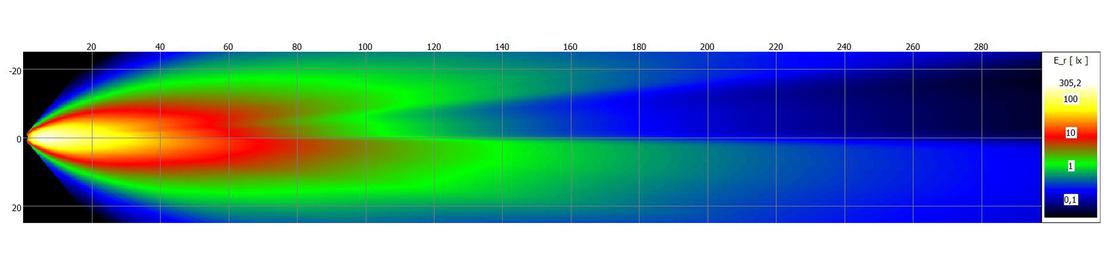

This modular system scales to your needs — from compact setups under 3 m to expansive 10–25 m measuring distances — and delivers precise luminous intensities, illuminances, and color coordinates for complex light sources. Achieve consistent, standard-compliant results from prototype analysis to production verification.

A complete solution tailored to your application

Assemble your BV room with proven TechnoTeam components:

- LMK 6 or LMK 6 color imaging luminance/metrology devices

- LID Table (for sample positioning)

- Optional further hardware: PC, power supplies

- Software: LabSoft (for R&D workflows), LID-Checker (for both R&D and EOL usage)

| Basic technical data | automotive1 | general lighting |

|---|---|---|

| Size of the device under test |

< 2 m | < 2 m |

| Typical measuring distance | 3.16 m to 25 m | 1 m to 3 m |

| Object field | hor. ±90° by vert. ±22° (3.16 m) hor. ±90° by vert. ±8.5° (10 m) |

Hor. ±180°; vert. ±90° depending on size of laboratory and positioning system |

| Resolution | 0.005° to 0.05° | 0.1° |

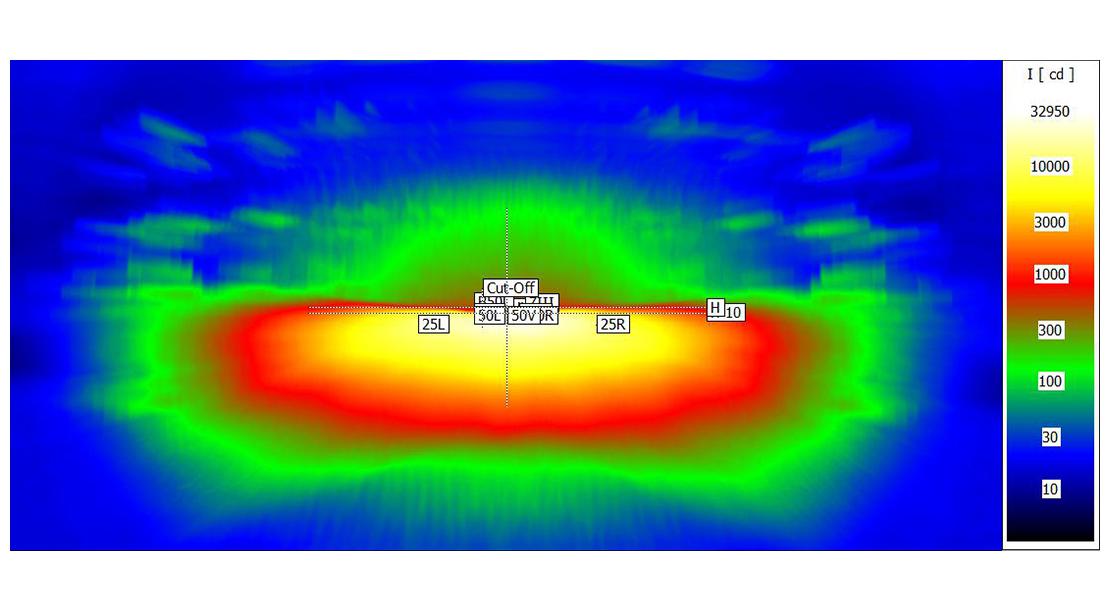

| Measuring range | 0.01 cd - 10 Mcd | 0.01 cd - 10 Mcd |

| Measurable contrast2 | 1:10 000 | 1:1 000 |

| Measuring time | seconds to minutes3 | seconds |

| Basic technical data | |

|---|---|

| Size of the device under test | automotive1: < 2 m general lighting: < 2 m |

| Typical measuring distance | automotive1: 3.16 m to 25 m general lighting: 1 m to 3 m |

| Object field | automotive1: hor. ±90° by vert. ±22° (3.16 m) hor. ±90° by vert. ±8.5° (10 m) general lighting: Hor. ±180°; vert. ±90° depending on size of laboratory and positioning system |

| Resolution | automotive1: 0.005° to 0.05° general lighting: 0.1° |

| Measuring range | automotive1: 0.01 cd - 10 Mcd general lighting: 0.01 cd - 10 Mcd |

| Measurable contrast2 | automotive1: 1:10 000 general lighting: 1:1 000 |

| Measuring time | automotive1: seconds to minutes3 general lighting: seconds |

2CIE244:2021 f25

3With image stitching

Why choose the BV room system?

- Flexible and scalable: tailored to small test samples or large-scale setups

- Broad measurement range: suitable for cd to Mcd levels, high contrast demands

- Modular components: integrates with LMK 6/LMK 6 color, LID Table, LabSoft, LID-Checker

- Full service offering: calibration, setup, maintenance, lab layout design

- Automotive-grade precision: patented solution in partnership with LMT for headlight testing

Your Next Step Toward Measurement Excellence

We ensure your BV Room system operates at peak precision through:

- Photometric calibration (cd, lx, lm, cd/m²)

- Geometric calibration (spherical / Cartesian coordinates)

- Laboratory layout design & consultation

- Ongoing maintenance, upgrades, and technical support

Bring world-class screen photometry to your laboratory.

Contact us to design a BV Room configuration that matches your testing requirements.