LMK LightChecker

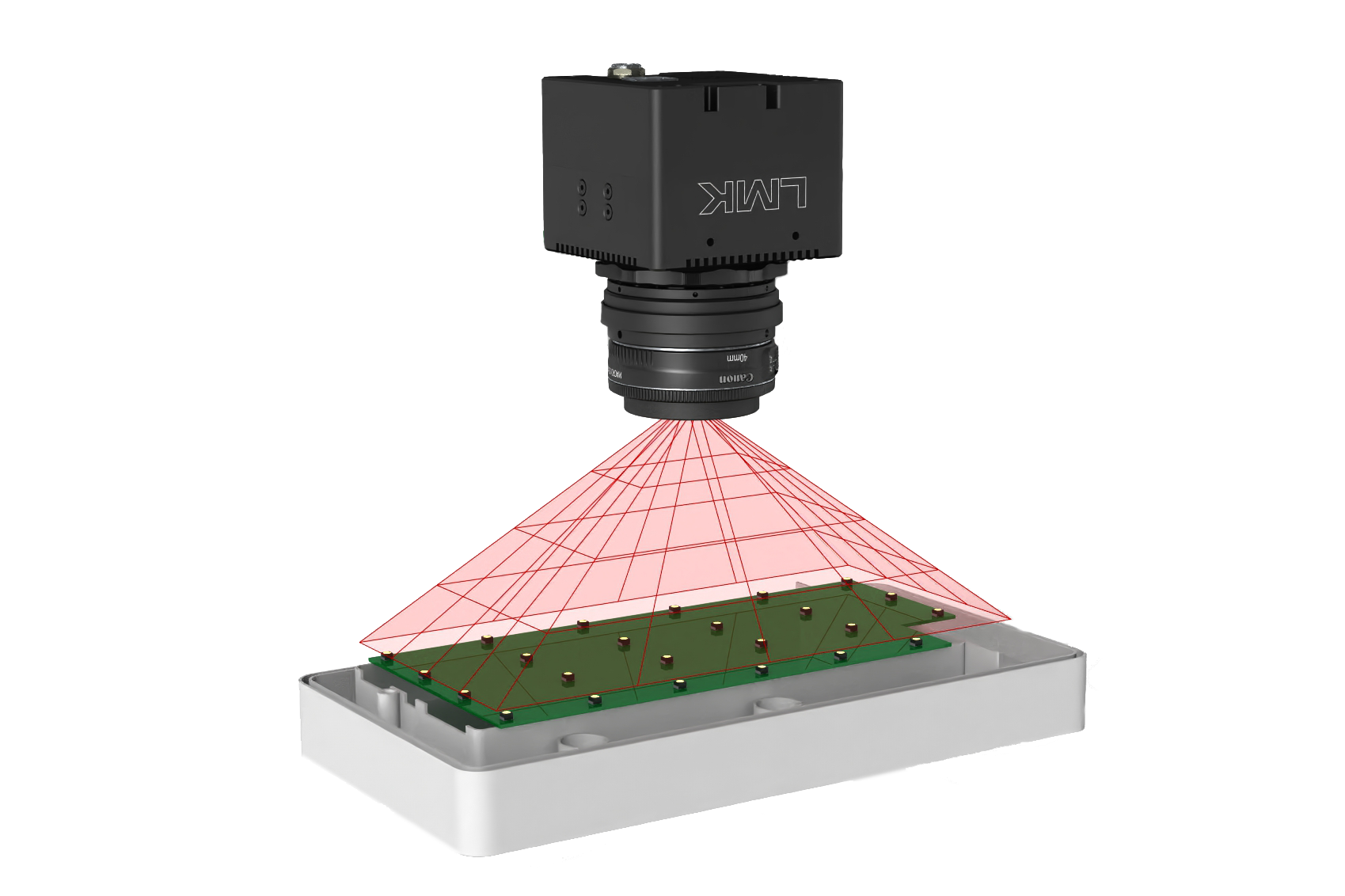

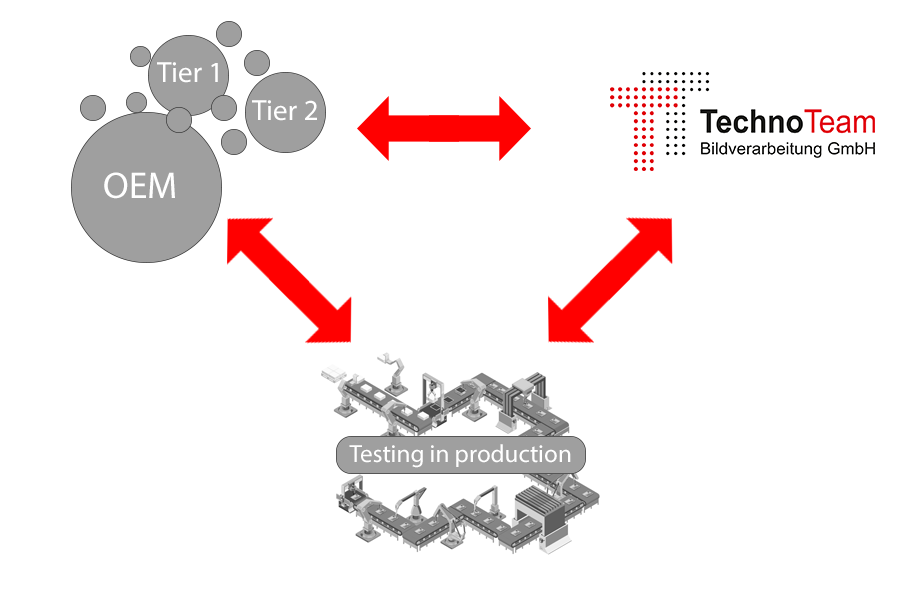

Our production-accompanying software LMK LightChecker combines efficient photometric measurement for short cycle times with automated evaluation options. LMK LightChecker offers various solutions for different requirements in the production line, such as the use of communication protocols (TCP/IP) to automate the entire system. In addition, the LMK LightChecker offers customized software functions for frequently occurring measurement tasks and objects with clearly defined test or requirement profiles.

The test data obtained is stored in predefined measurement protocols.

The LMK LightChecker is available in the following versions: SymbolChecker, LEDChecker and LIDChecker

SymbolChecker

The SymbolChecker is an application of the LMK LightChecker, which enables the automated measurement of the average, maximum, and minimum luminance of a backlit symbol. In addition, further quality criteria, such as uniformity can be automatically determined from this measurement data. In combination with an LMK color, automated color measurement for testing color tolerances is also possible.

This application is designed for measurements and tests of backlit symbols in the interior of the automotive industry but is also increasingly used for the evaluation of small and very small display surfaces.

With the help of a simple user interface, reference symbol data can be learned quickly and close to the process to evaluate the symbol quality of the test specimen by sampling.

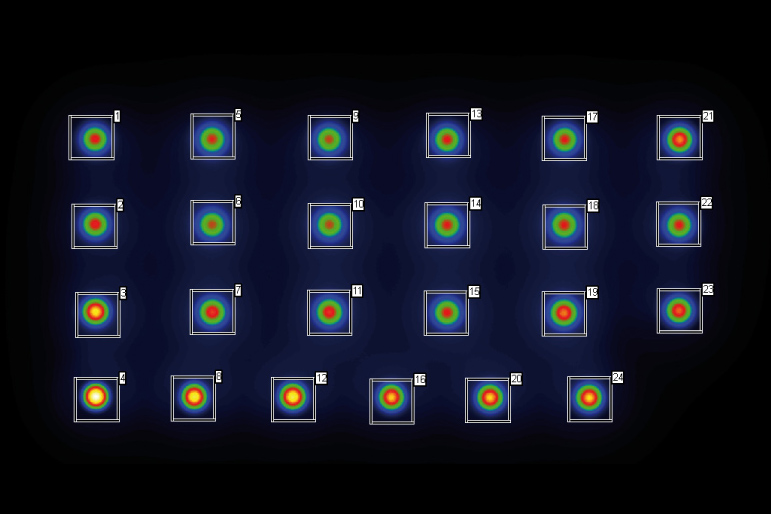

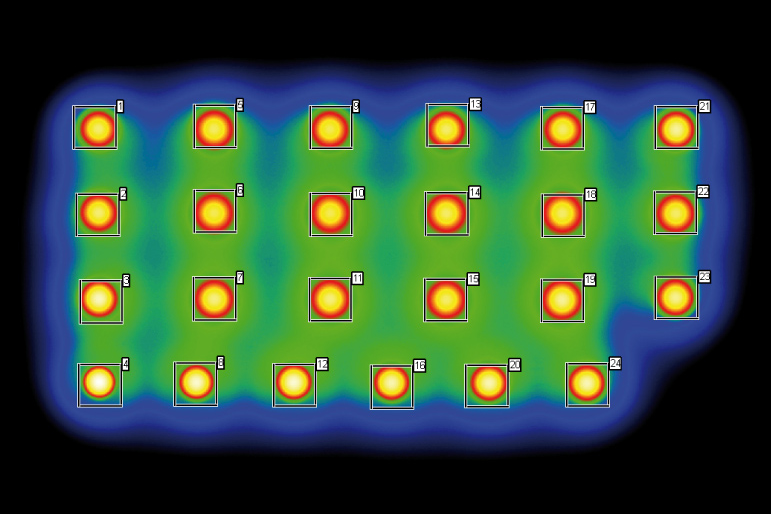

LEDChecker

The LEDChecker is an application of the LMK LightChecker that performs an automated measurement of the luminance or color of individual LEDs or LED assemblies. The test information derived from this is luminance and color differences, or color distances between these assemblies. For emergency luminaires, for example, the measurement of each individual LED is mandatory. For this task, a well adapted and absolutely calibrated camera measuring system is required. For example, it must be possible to produce measurement images with a high dynamic range for different

light colors as well as light intensities and luminances. In addition, geometric information on the position and orientation of the LEDs on the assembly is also checked.

All this information can only be determined with imaging luminance and colorimetric camera systems. The LEDChecker application includes software-based image processing operations specifically tailored to such measurement tasks. For example, LEDs can be automatically detected and separated from each other in the measurement image.

LIDChecker

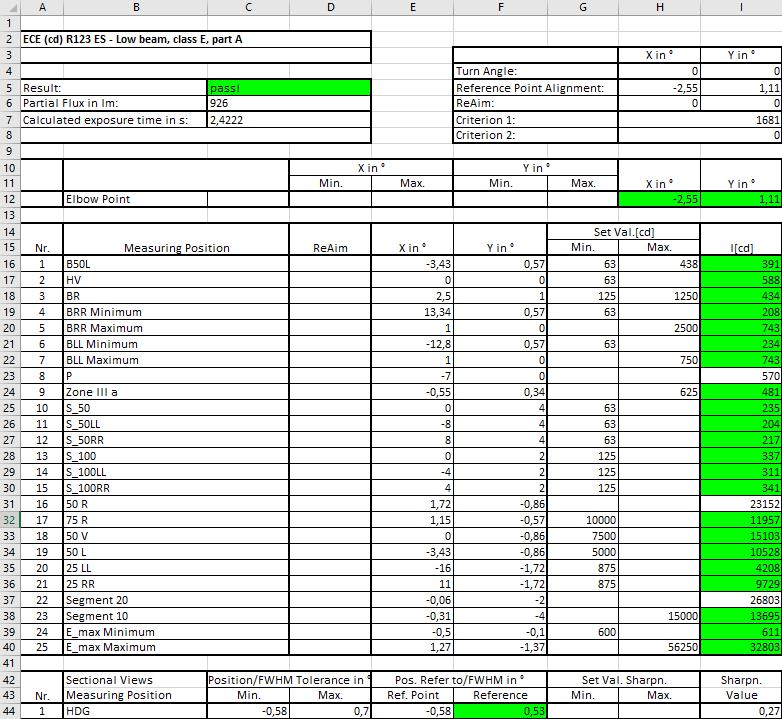

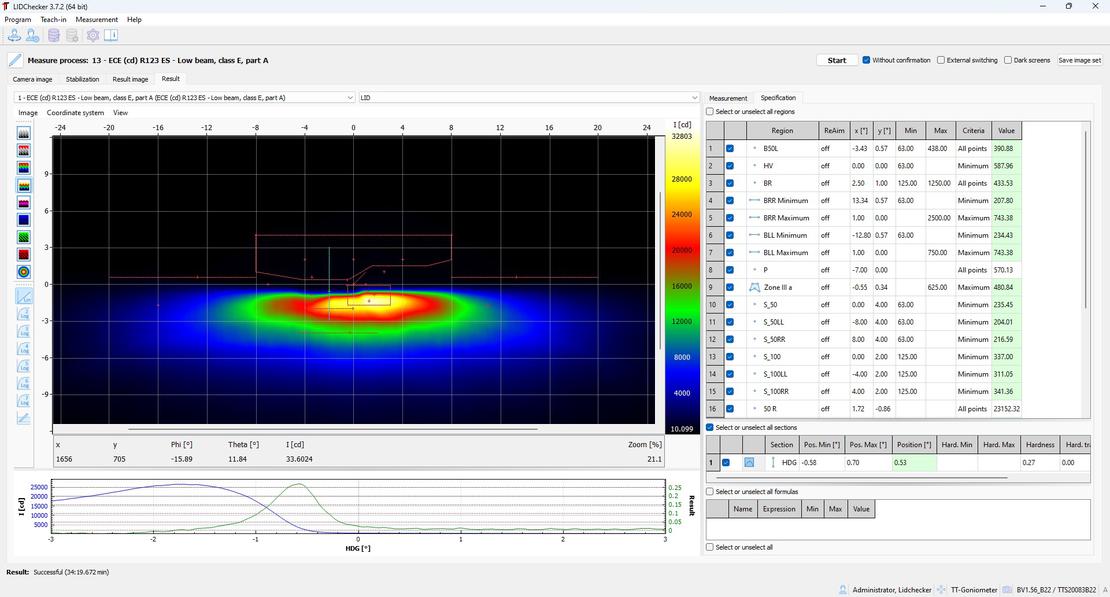

The LIDChecker is used for fully automated testing of objects whose LID needs to be recorded. To do this, a test plan is manually entered into the LIDChecker database once before the measurement. The test plan can include tests in accordance with SAE, ECE, CCC, or similar standards. This type of test plan must be loaded before the measurement. During the measurement, the measured values are recorded and evaluated automatically. At the end of the evaluation, a test report is created containing the entered test regions, sections, and calculations, their tolerances, and the recorded measured values. The final result also shows whether the test specimen has passed or failed. Furthermore, individual partial results, such as the photometric values along a section, can be output to use these data for your own evaluations.

Below is an example of a test report for an automotive headlamp tested per ECE regulation R123.

With LIDChecker version 3.8, the testing of color values has also been implemented. This means that regions in the captured color image can be checked to see whether all pixels lie within a freely definable zone (e.g. ECE white) in the horseshoe diagram of the 2° observer of the CIE xy color space.

- Tasks:

- Automation & Industry