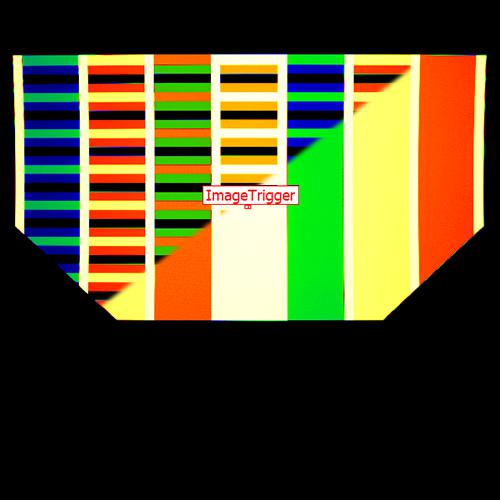

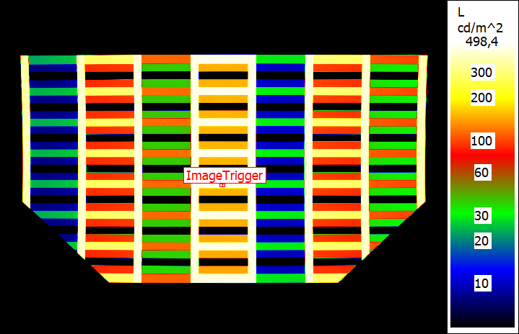

Three-level burn-in pattern for color sticking image measurement with our image-content trigger setup

LMK Sticking Image - Precise Measurement of Display Burn-In and Image Retention

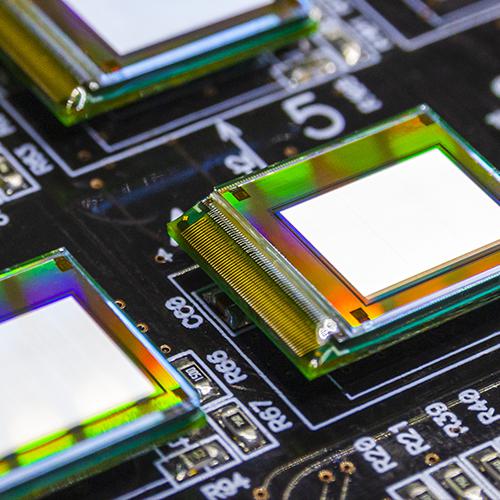

Image retention, ghosting, and burn-in are critical concerns in display quality and durability. These phenomena impact performance, lifetime, and visual quality. The LMK Sticking Image add-on provides a precise, standardized method to measure these effects, and it can be integrated into existing measurement workflows. LMK Sticking Image can be used for LCDs and OLEDs as well as other technologies prone to Image Sticking, especially in applications showing static or partially static content, e.g. in the automotive or public information sector.

Patented Content-Based Triggering & Measurement Methodology

All LMK imaging photometer systems are capable of conducting image sticking test series. A display under test is exposed to a burn-in phase with defined patterns, followed by relaxation phases where the luminance distribution is recorded.

A key feature is the patented content-based trigger. This ensures correct temporal alignment of the relaxation measurements with the displayed content, independent of device-specific input lags or timing uncertainties.

Two- and Three-Level Evaluation Procedures for Reliable Results

Our LMK Sticking Image Add-On can be used to analyze the display burn-in behavior according to two established procedures:

Burn-in pattern and relaxation images of a three-level measurement series

Three-level approach by Dr. Lauer

- Can be extended to color sticking image

- Method adapted by the German Flat Panel Forum (DFF)

- Local or temporal non-uniformity correction possible

Burn-in pattern and relaxation images of a two-level measurement series

Two-level approach by Dr. Bauer

- Including automatic pattern rolling for warm-up

- Classical checkerboard burn-in pattern

- High precision temporal-based non-uniformity correction

Advantages of LMK Sticking Image

- Fast and precise measurement of image retention effects

- Patent-protected trigger method for reliable synchronization

- Flexible evaluation procedures (two-level, three-level, custom setups)

- Seamless Integration with existing LMK measurement setups

- Compliance with established standards in display measurement technology using DFF and OEM methods

Integration and Related Solutions

LMK Sticking Image is part of the TechnoTeam Display Package, ensuring compatibility with other LMK-based measurement solutions.

RELEVANT PRODUCTS AND APPLICATIONS

Downloads

Publications

Internation Display Workshop (IDW 2020)

SID Vehicle Displays & Interfaces 2019

This contribution concentrates on the performance of two selected image sticking evaluation methods [5, 6] from the automotive community and [1] for reference. After briefly introducing the three methods, this contribution focusses on their capability of separating initial non-uniformities from the actual sticking image effect of the target display. Therefore, a mathematical analysis, which is based on a simple but physically motivated sticking image model, is performed. Based on that, an additional non-uniformity correction is proposed. This additional correction has a positive influence on the precision but a negative influence on the measurement time of the fastest measurement method [6]. Thus, we propose a workflow, that decides based on the properties of the DUT whether the correction is necessary or not. All conclusions are supported by simulations and validated using measurement results of a randomly chosen non-uniform automotive LC display.

The aim of this paper is on the one hand to quantize the mathematical influence of the methods and on the other hands to suggest a workflow, which utilizes an existing method and optimizes its application with respect to precision and overall measurement time.

Society for Information Display

- Type:

- Add-On

- Applications:

- Automotive Aviation Display

- Measurands:

- Light measurement

- Tasks:

- Development & Industry