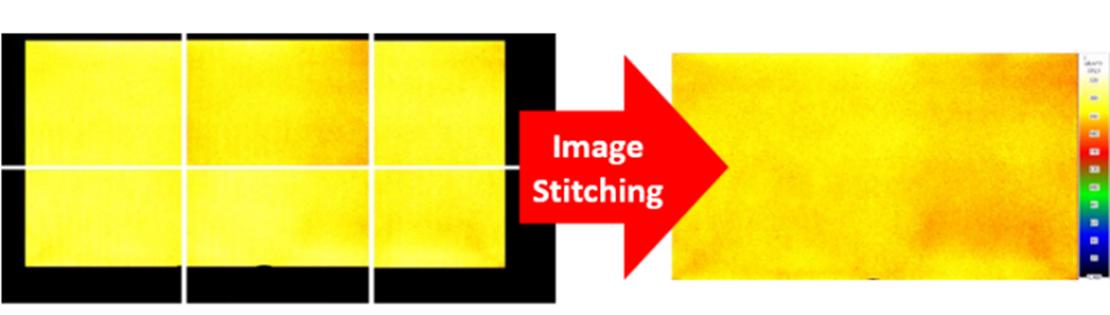

Basic concept of image stitching: individual measurements are combined to form one result image

LMK Image Stitching: Efficient measurement of ultra-wide displays with intelligent image fusion

Why image stitching?

Modern ultra-wide displays (e.g. with an aspect ratio of 21:9, 32:9, or 6:1) push conventional measurement systems beyond their limits. The sensor area is used inefficiently, while resolution is insufficient. With LMK Image Stitching (part of the display package), TechnoTeam provides a powerful extension for high-resolution luminance measurement of displays with large or unusual aspect ratios. Several individual images are merged into one seamless, high-resolution overall image, without any loss of measurement accuracy.

READ THE TECHNICAL ARTICLE: "FAST AND ROBUST HIGH PRECISION LUMINANCE IMAGE STITCHING"

Want to know more about how our image stitching works? Then check out our technical article (external link), where we present our method in detail.

How LMK Image Stitching Works

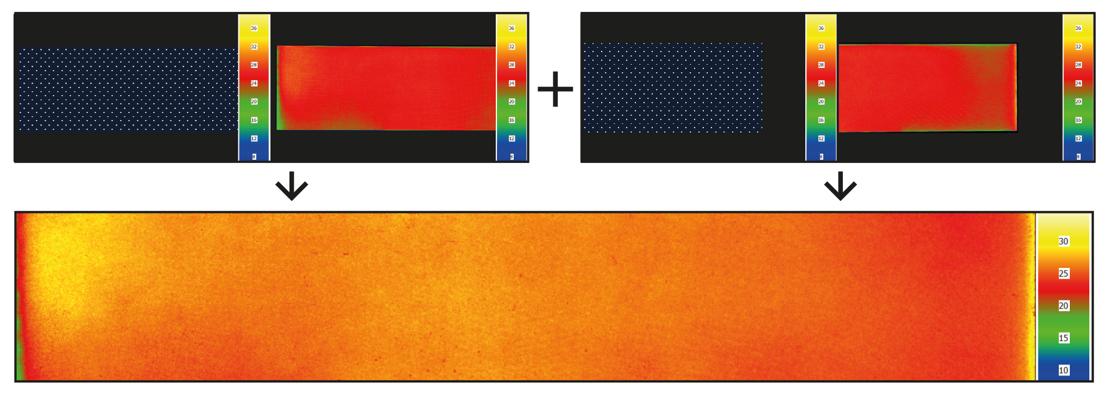

Multiple images are captured and combined into one continuous luminance image. The core of the process is our Advanced Pixel Registration (APR) method:

- Separation of position detection and luminance measurement: Ensures distortion-free, pixel-to-pixel mapping.

- Direct measurement in display coordinates: No post-processing or geometric adjustments required.

The result: a robust, precise, and efficient solution for large-area or slightly curved displays

For even greater efficiency, the stitching process can be fully automated in LMK Position, our robotic measurement system. Combined with TechnoTeam’s short-distance uniformity correction (external link to our technical article), this automation ensures perfectly consistent results and eliminates potential waviness artefacts, making high-precision luminance stitching not only faster but also more reliable in both lab and production environments.

Your Benefits at a Glance

- Higher resolution by combining multiple captures

- Greater efficiency through optimal utilization of sensor area

- Accurate fusion thanks to pixel registration with APR

- Cost savings by using an LMK with any resolution

- Scalability from laboratory setups to fully automated production environments

APR Technology in Detail

- Registration image: Exact localization through targeted activation of display pixels

- Luminance test image: High-precision luminance measurement.

- Stitching: Merging of multiple images directly in the display coordinate system.

RELEVANT PRODUCTS AND APPLICATIONS

Publications

International Conference on Display Technology (ICDT 2021)

SID Vehicle Displays & Interfaces 2022

Journal of the Society for Information Display

SID Vehicle Displays & Interfaces 2021

- Type:

- Software