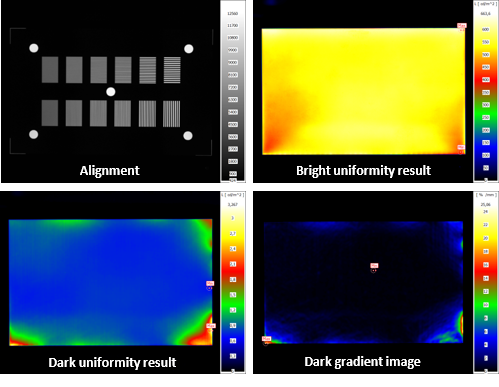

BlackMura procedure consisting of: Alignment; Light uniformity; Dark uniformity; Dark gradient

LMK BlackMURA - Standardized uniformity measurement of displays

Uniformity measurement according to standard

LMK BlackMURA Features at a Glance

- Full compliance with DFF BlackMURA

- Full-surface uniformity assessment of the display

- Adaptable for special cases such as DeepgrayMURA in OLEDs

- Compatible with image stitching and pillar-to-pillar displays

- Reproducible results thanks to standardized alignment

- Automation possible via SDK and the LMK Position robot platform

- Usable in confined spaces near production lines thanks to short-distance correction

- Projective distortion correction for angle-dependent analyses, e.g., for split-view displays

Simple 3-Step Procedure with Live View

The BlackMURA measurement is performed using a straightforward three-step process following an initial alignment:

- White image measurement to assess bright uniformity

- Black image measurement to detect dark non-uniformities

- Gradient analysis to evaluate local contrasts and brightness transitions

Thanks to the integrated live view mode of the LMK luminance measurement camera, camera alignment is fast and intuitive: position and angle can be checked and adjusted in real time. Flexible adaptations such as grayscale modifications (e.g., DeepgrayMURA for OLEDs) and full automation via SDK or the LMK Position platform ensure precise and reproducible results.

Corrections for Compact Measurement Environments

The short-distance correction developed by TechnoTeam (external link to our technical article) enables BlackMURA-like evaluations even in confined spaces – ideal for compact production lines. At the same time, it can be combined with image stitching for large-format displays (e.g., pillar-to-pillar), where multiple camera perspectives are precisely merged into one overall image through lateral movements (external link to our technical article).

RELEVANT PRODUCTS AND APPLICATIONS

Downloads

Publications

Society for Information Display 2021

Journal of the Society for Information Display

Proceedings of the International Display Workshops Volume 26 (IDW '19)

Society for Information Display

SID International Symposium 2016

- Type:

- Add-On

- Applications:

- Automotive Display

- Measurands:

- Light measurement

- Tasks:

- Development & Industry