Automotive Display

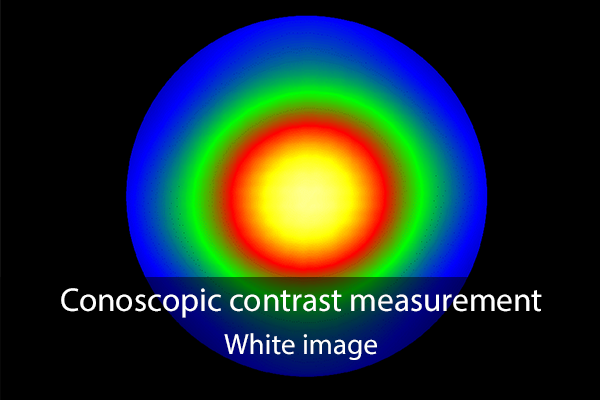

Displays in Fahrzeugen dienen als Kombiinstrument (IC) oder Head-up-Display (HuD), um dem Fahrer wichtige Informationen anzuzeigen, als zentrale Informationsanzeigen (CID) oder als Beifahrer- oder Rücksitz-Displays zur Unterhaltung. Teilweise ersetzen sie sogar die Seitenspiegel. In Fahrzeugen sind dem Design und den Formfaktoren der Displays keine Grenzen gesetzt (Beispielsweise Curved Displays). Sie verfügen teilweise über verschiedene Funktionen wie Bildoptimierung, Privatsphäre-Modi, Entspiegelung usw.. Die Displays müssen großen Temperaturunterschieden, Vibrationen und Erschütterungen standhalten und gut lesbare Inhalte unter wechselnden Lichtverhältnissen anzeigen. Außerdem müssen sie aus verschiedenen Blickwinkeln gut lesbar sein um Menschen verschiedener Größe und auf diversen Sitzposition von Nutzen sein zu können.

Messaufgaben

Das Deutsche Flachdisplay Forum (externer Link), ein führendes Expertennetzwerk im Bereich Displays, hat zusammen mit der Arbeitsgruppe OEM Empfehlungen für Automobildisplays entwickelt. Diese umfassen Spezifikationswerte und Methoden für optische Tests. Sie gelten für alle Arten von automobilen Displays. Beispiele sind:

- OEM Spezifikationen

- DFF OLED Spezifikationen

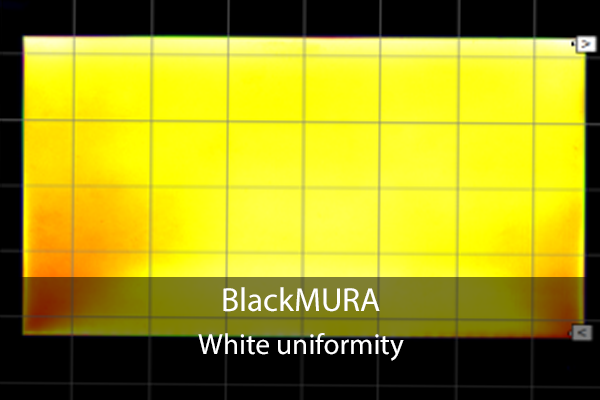

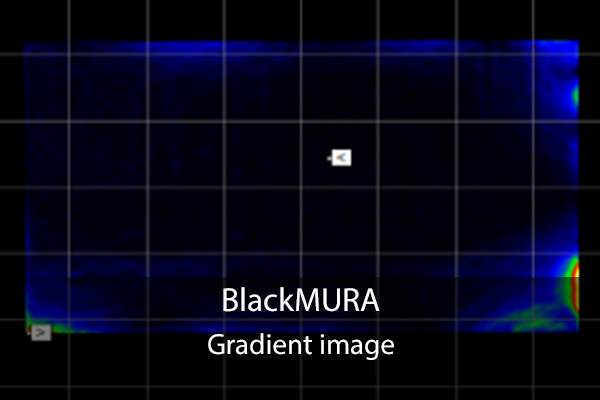

- DFF BlackMURA

- DFF Gamma

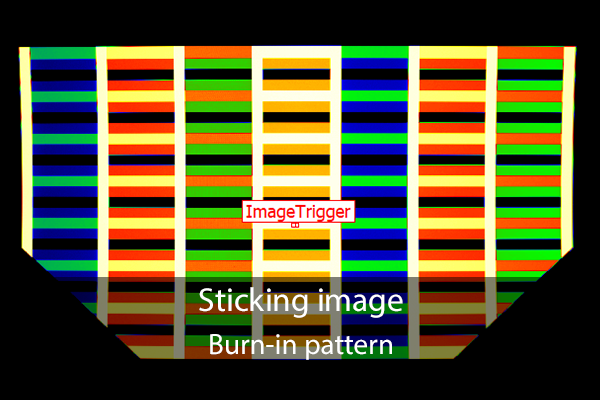

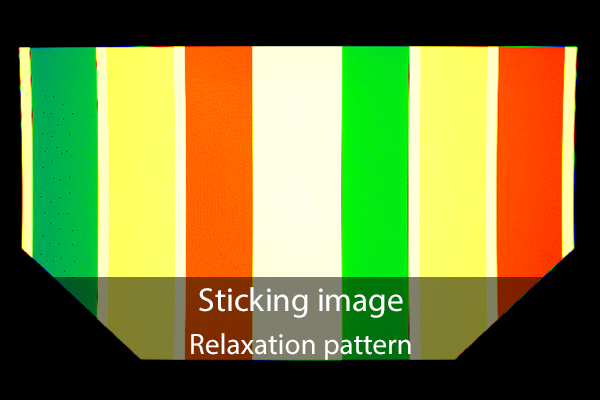

- DFF Sticking Image (3-level)

- Winkelbereiche der OEMs

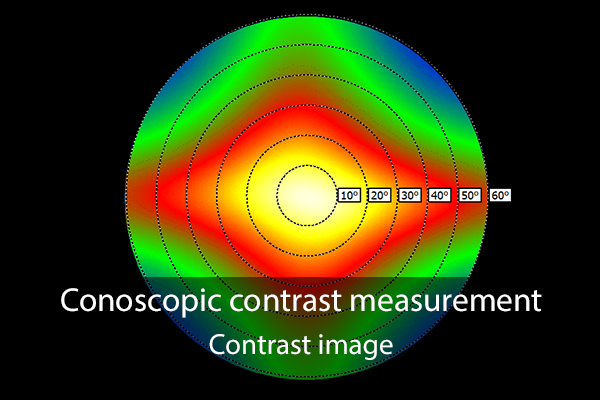

Insbesondere Premiumhersteller haben zusätzliche Spezifikationen erstellt, um die Lesbarkeit und höchste optische Qualität zu gewährleisten. Viele dieser Messungen wurden in Projekten zusammen mit TechnoTeam entwickelt, bewertet und/oder erforscht. Dazu gehören zum Beispiel:

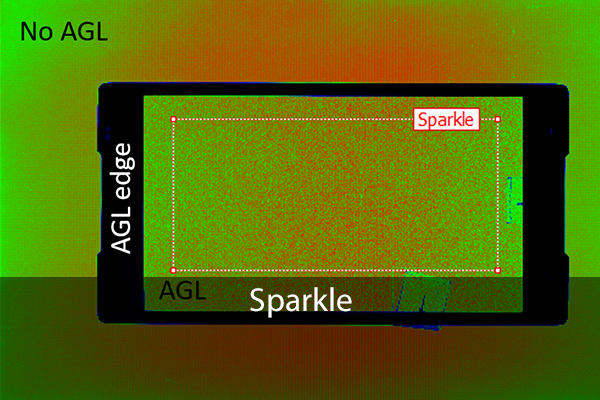

- Display Sparkle für Anti-Glare-Layer (AGL)

- Sticking Image (2-level)

- Reflexion für Kontrast bei Umgebungslicht

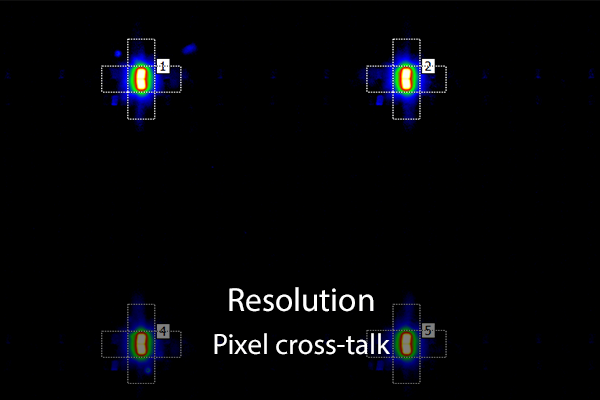

- Auflösung durch Pixel Cross Talk

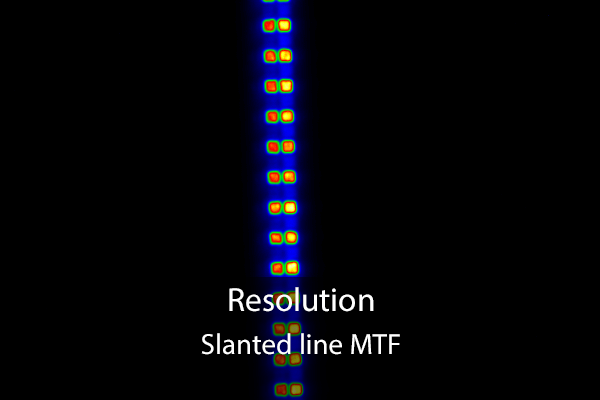

- Auflösung durch Modulationsübertragungsfunktion

- Halo für Full Area Local Dimming Display (FALD)

- Alle vorherigen Messungen aus Fahrer/Beifahrerposition

Unsere Lösung

TechnoTeam bietet eine Vielzahl von speziellen Hard- und Softwarelösungen an, um schnelle und reproduzierbare Messungen gemäß all diesen Spezifikationen und Methoden zu gewährleisten. Das LMK Position ist ein spezielles roboterbasiertes System für unsere Leuchtdichtemesskameras, das eine schnelle und äußerst reproduzierbare Ausrichtung an Displays mit verschiedenen Geometrien - auch unter Blickwinkel - gewährleistet, einschließlich ultrabreiter Bildschirme und Freiformflächen, wie sie in modernen Autos üblich sind. Weitere Informationen zu den einzelnen Produkten und Anwendungen finden Sie in den nachstehenden Links:

RELEVANTE PRODUKTE

RELEVANTE PUBLIKATIONEN

SID 2025

IDW 2024

Society for Information Display 2025

Information Display 2025

International Display Workshop (IDW 2023)

International Conference on Display Technology (ICDT 2023)

Journal of the Society for Information Display

International Conference on Display Technology (ICDT 2021)

Society for Information Display

Society for Information Display

SID Vehicle Displays & Interfaces 2021

Electronic Display Conference 2016

SID Vehicle Displays & Interfaces 2019

This contribution concentrates on the performance of two selected image sticking evaluation methods [5, 6] from the automotive community and [1] for reference. After briefly introducing the three methods, this contribution focusses on their capability of separating initial non-uniformities from the actual sticking image effect of the target display. Therefore, a mathematical analysis, which is based on a simple but physically motivated sticking image model, is performed. Based on that, an additional non-uniformity correction is proposed. This additional correction has a positive influence on the precision but a negative influence on the measurement time of the fastest measurement method [6]. Thus, we propose a workflow, that decides based on the properties of the DUT whether the correction is necessary or not. All conclusions are supported by simulations and validated using measurement results of a randomly chosen non-uniform automotive LC display.

The aim of this paper is on the one hand to quantize the mathematical influence of the methods and on the other hands to suggest a workflow, which utilizes an existing method and optimizes its application with respect to precision and overall measurement time.

SID Vehicle Displays & Interfaces 2018

Based on the general working principle of ILMDs (imaging luminance measurement device), we briefly explain typical ILMD characteristics as well as the concepts of repeatability, reproducibility, precision and measurement uncertainty [1]. Afterwards, optical display properties as well as measurement methods [2, 3, 4] are introduced.

Finally, we qualitatively and quantitatively assess chosen influences of ILMD specifications and different measurement procedures on the obtained results.

Thus, this work shall convey a feeling for photometric display metrology requirements under the consideration of the measurement task and the desired precision